Product Features

Core

Impact Series panels have a compound core of a face layer of 1/8” high-density, 16-20 pcf molded fiberglass laminated to Owens Corning 707 fiberglass — a 7 pcf (pounds per cubic foot) density board with superior surface smoothness, sharp edge detail and dimensional stability. The molded fiberglass sheet gives the Impact panel impact-resistance and tackability and also increases the sound absorption in the lower frequencies.

Recycled Content

Impact Series panels use the Owens Corning 707 fiberglass board core that is eligible to bear the Green Cross label for recycled content. 707 is certified on average to contain at least 35% recycled glass, with 9% post-consumer, and 26% pre-consumer content.

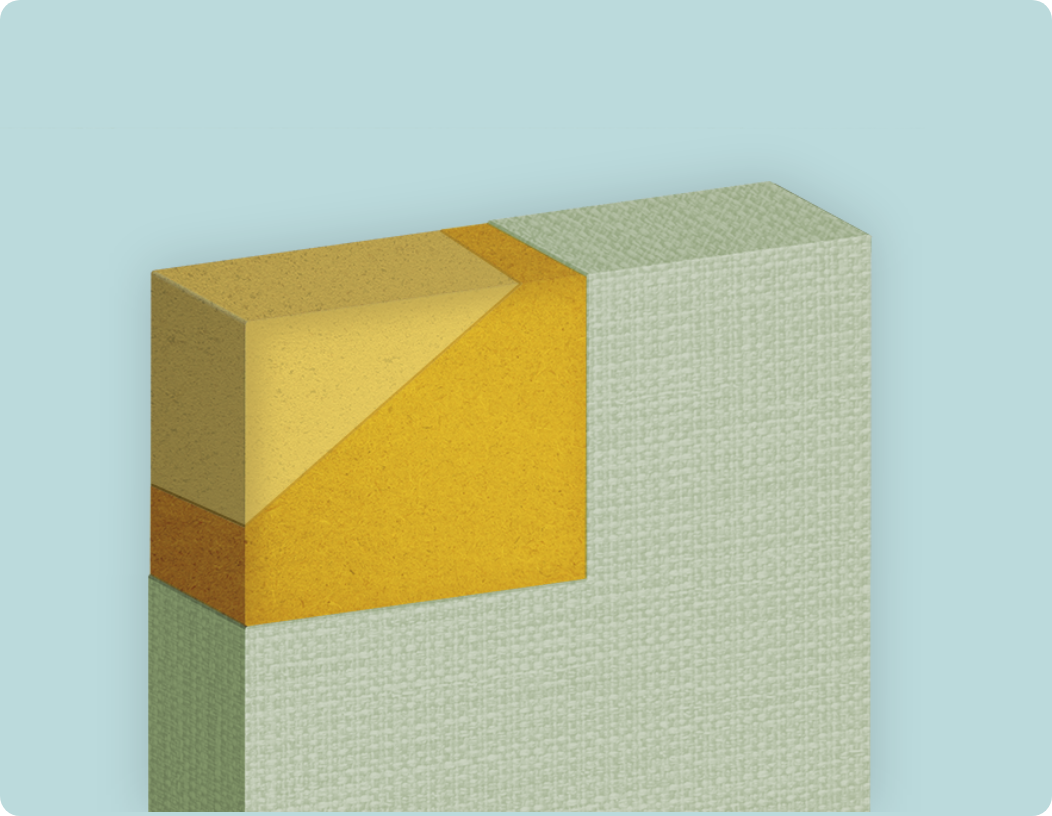

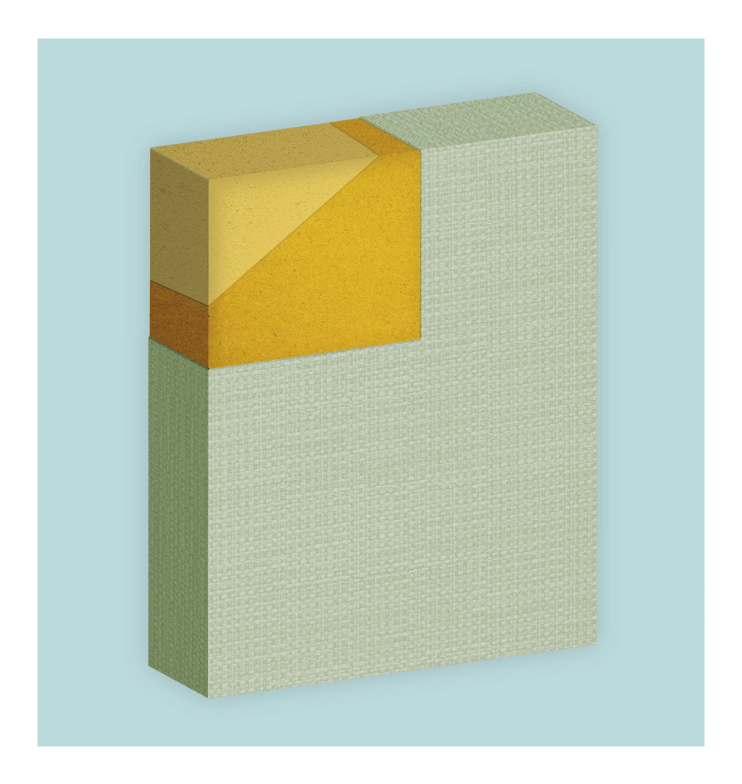

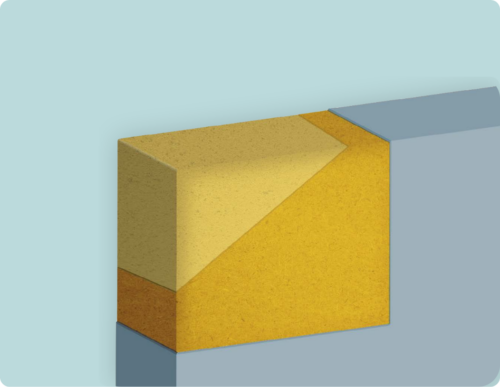

Edge Details

All edges are resin hardened, unless otherwise requested. Edges can be square or beveled. Beveling options are many, including full reverse mitering for corners.

Materials sourced in the USA.

Technical Details

Fire Rating

All components of the Impact Series panels conform to ASTM E84 and are rated Class I/A.

Acoustical Performance

| Thickness |

NRC |

| 11⁄8“ |

.90 |

| 15⁄8“ |

1.00 |

| 21⁄8“ |

1.10 |

| 31⁄8“ |

1.15 |

| 41⁄8“ |

1.25 |

Warranty

Impact Series panels are warranted to be free from defects in material and workmanship for 3 years from date of purchase.

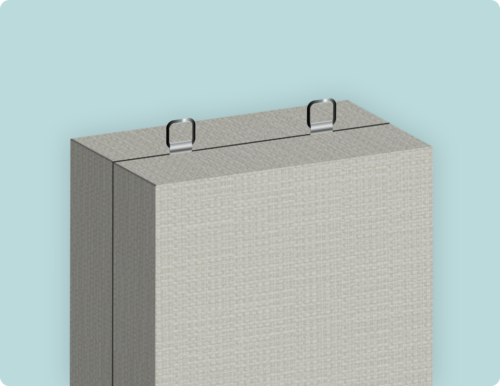

Mounting

Standard mountings include impaling clips with perimeter adhesive, Z-clips, wall bars, concealed kerf/splines and hook-and-loop. Standard ceiling mountings include wall bar to wall bar or lay-in. Cloud mounting is accomplished with acoustical anchors — eyelet or D-ring — embedded in resin spots on the back. A white fiberglass scrim is recommend for the backs of clouds to eliminate any possibility of airborne migration of particulates.